Deep Anode Groundbed Installation

Standard Recommended Practice External Cathodic Protection of On-Grade Carbon Steel. Installation, and maintenance. Deep Anode Groundbed.

Durammo is the only complete, factory assembled, ready to install deep anode system available. Over 8,000 Durammo Deep Anode Systems, in operation for more than 200 million hours over 30 years, have successfully protected pipelines, wells, plants and infrastructure from corrosion. Patented MATCOR Kynex®connection technology and fast, reliable installation make Durammo the leading deep anode system in the world. 100% factory made in MATCOR’s USA, facility, Durammo is a complete deep anode system that installs in minutes without field assembly. Kynar® cables, SuperVent™, mixed metal oxide (MMO)anode, Kynex connections, connection links, bottom weight and lowering rope are shipped complete on one reel, eliminating the time and risk involved in field assembly.

Diagram of the Loresco Replaceable Deep Anode System.TM U.S. Patent Nos: 3,725,669 4,786,388 5,026,508 REPLACEABLE DEEP ANODE SYSTEM TM Loresco Replaceable Deep Anode System TM (U.S. Patent Nos: 3,725,669; 4,786,388 & 5,026,508) The Loresco Replaceable Deep Anode System TM allows for the inevitability of failure of deep anode systems to occur without the painful cost of drilling new bore holes. Since its introduction, the Loresco Replaceable Deep Anode System TM has been well received by the corrosion industry. Currently, there are thousands of systems operating in Japan, Canada, the United States, South America, North Africa, and the Middle East.

Its design permits positive backfill placement in order to maximize the life of the anode system. Xilinx Ise 9 1 I Plus. The Loresco system is extremely versatile and systems have been designed ranging from 2 amps to 250 amps. Advantages: • Can be located in congested areas where surface ground beds pose geographic, topographic, or right-of-way problems. • Provides lower groundbed-to-earth resistance than shallow ground beds in areas of high resistivity surface soils. • Lowers anodic potential gradients to other structures more than shallow ground beds.

• Provides better current distribution than shallow ground beds. • Virtually eliminates accidental damage which might occur to shallow ground beds by excavation and land cultivation. • Less effected by seasonal moisture variations, and is not subject to freezing. • Inspection, replacement or repair is simple and inexpensive. Planning and Design Successful installations require advance planning.

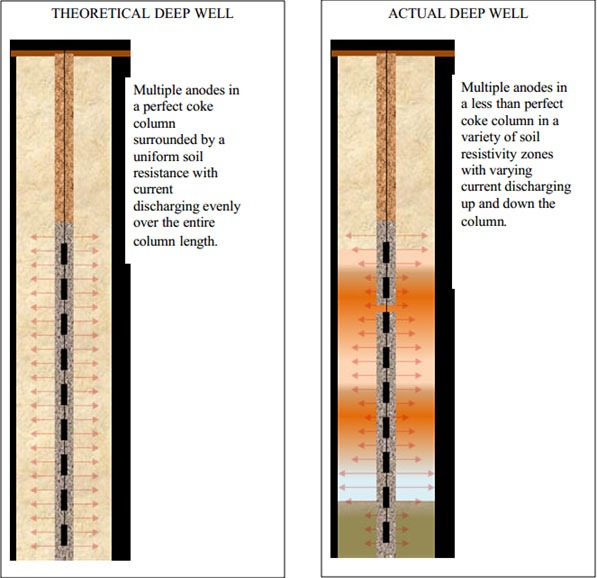

Once the design current output of the deep anode system has been determined, it is necessary to investigate the geology at the proposed installation location. With knowledge of the subsurface soils, the design engineer can estimate the depth of completion, determine the required hole diameter, and select the proper casing size and active length. Some of the sources for geological data include: • U.S. Geological Survey (USGS) • State Geologist • U.S.